|

Hybrid components

2003 - 2009

from toyota japan

-

1.5 litre VVT-i engine running on the Atkinson Cycle

-

Hybrid Transaxle

-

High

voltage NiMH battery pack

-

Power Inverter

-

Mechanical power-split device

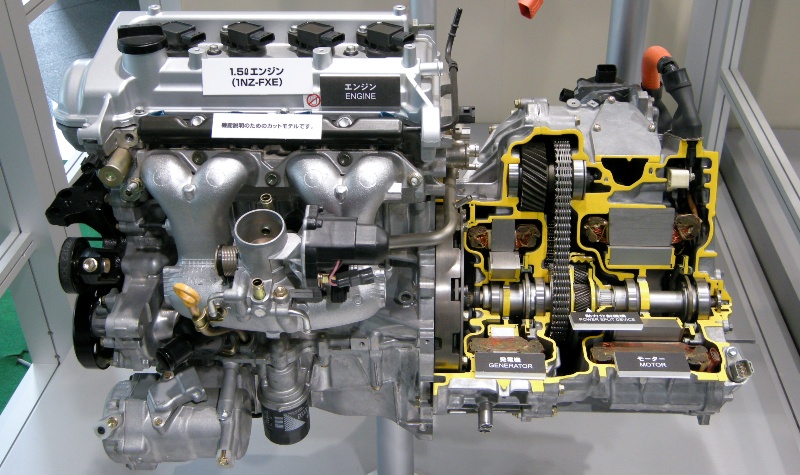

1.5 Litre VVT-i engine Top

The 1NZ-FXE Engine

mated to the hybrid transaxle (right). The Prius engine uses the more efficient

Atkinson cycle.

Everything neatly tucked away. The engine is on the

left underneath the

air filter. The inverter sits

on top of the hybrid transaxle on the right.

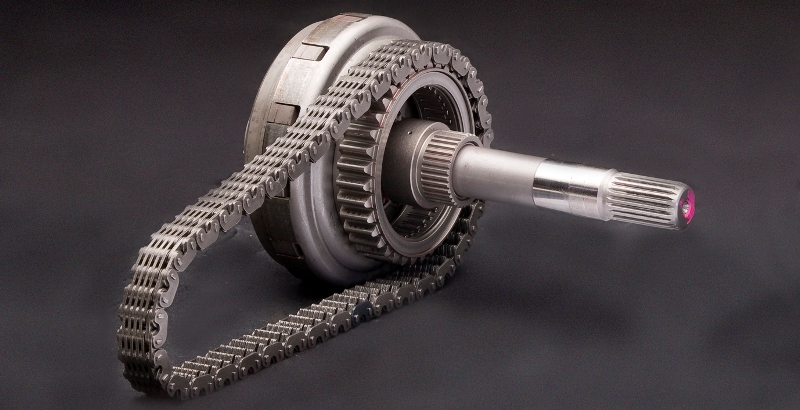

Hybrid Transaxle Top

The Prius transaxle contain two electric motors that

can also act as generators (motor/generator or MG). The gears sticking out

in-between, couple the drive force to the wheels. The

power-split-device resides between

the two motors and together with the two motors create a type of continuously

variable transmission.

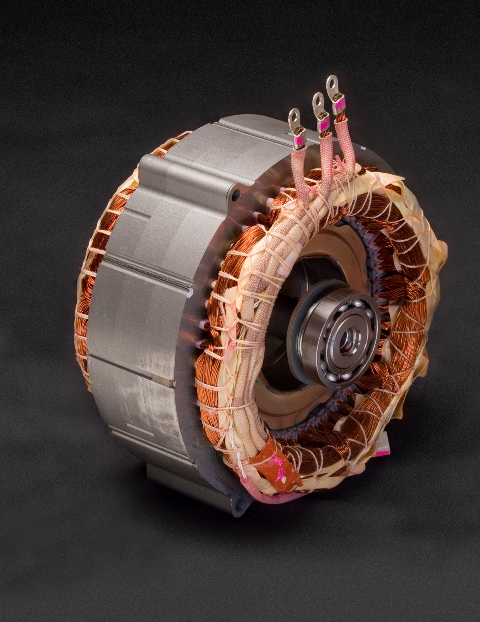

Motor/Generator 1 |

Motor/Generator 2 |

High

voltage NiMH battery pack

Top

Prius HV battery with cooling ducts

Toyota uses prismatic NiMH modules from

Panasonic. Each module consists of six 1.2 V cells connected in series. The

module has a nominal voltage of 7.2 V, capacity of 6.5 Ah, weighs 1.04 kg, and

has dimensions of 19.6mm(W) x 106mm(H) x 275mm(L).

Further notable features are as follows:

- A thermal well on top of the cell allows measurement of an approximate

internal temperature of the electrolyte,

- A hydrogen vent provides for release of hydrogen through a manifold under

gassing conditions,

- Terminals on each side provide clean connections,

- Tie down bolts secure the modules to structural supports,

- A plastic case lowers mass, and

- The side surfaces of the module provide air gaps for airflow created by

dimples and protrusions when two modules are stacked. This Panasonic design has

improved in specific energy and power capabilities over the first generation

cylindrical cells that are in the 1997 - 1999 Japanese Prius

"Toyota says its out-of-warranty

battery replacement rate is 0.003 percent

—or one out of 40,000 Priuses—for

the second generation Prius"

First Numbers on Hybrid Battery Failure

"At 5 years and 106,500 miles,

mine is still going strong."

john1701a Senior Member Priuschat

The Pack

The Prius battery stack consists of 38 prismatic NiMH modules connected in

series. It delivers a nominal 273.6 Volts and has a 6.5 Ah capacity. The modules

are stacked side by side and then compressed together in a rigid, non-expandable

structure that prevents expansion from internal pressures. The complete battery

pack consists of the battery stack, enclosure for structural support and

airflow, battery electronic control unit/monitor, relays and safety switch. The

weight of the complete battery pack is 53.3 kg. The pack is horizontally

positioned in the boot of the vehicle partially under the back seat. Power

electronics (inverter, DC-AC converter) are under the bonnet and a blower for

moving air and associated air ducts are in the boot. Discharge power capability

of the Prius pack is around 20 kW at 50% SOC with regenerative capability of

14.5 kW at 2C. The power capability increases with higher temperatures and

decreases at lower temperatures. Active thermal management can improve power

capability at lower temperatures.

Battery Pack Thermal Management

The purpose of a battery thermal management system is to keep the batteries

operating within a desirable temperature range; prevent the batteries from

exceeding a high temperature limit that can damage the batteries and/or reduce

life; and maintain battery temperature variations to low levels to prevent

highly imbalanced batteries. Pack imbalances can reduce performance and can also

damage the battery and/or reduce life. Thermal management of the battery pack is

typically accomplished with the combination of two approaches. First, a

cooling/heating system is designed to extract/supply heat to the battery pack.

Second, the battery controller adjusts the vehicle’s use of the battery pack

based on the conditions in the batteries.

In the rear is a vent that draws cabin air in and over the

battery for temperature control. It is important not to block this vent.

Forced Air System

The Prius supplies conditioned air from the cabin as thermal management for

cooling the batteries. The pack’s forced air system consists of two vents

located in the cabin under the middle brake light (exhaust from the cabin or

inlet to the pack); ducting to the battery pack enclosure; the enclosure

manifold; air gaps between modules; ducting out of the pack to a blower that

pulls the air through the system; and two exhausts (one to the boot and the

other to the outside). A hydrogen vent from each module is connected in series

with tubing. Any gases released are exhausted from the vehicle through the gas

manifold to avoid any increased hydrogen concentration and, thus, potential for

explosion. Outside air is conditioned (heated or cooled) by the vehicle’s

thermal comfort system to a level comfortable for the driver. This approach has

the advantage of providing air that is not only comfortable to the passenger(s),

but also ideal for use in heating or cooling the NiMH batteries. However, the

Prius does not use the forced air for heating the batteries.

To achieve a

relatively uniform temperature distribution across the modules, a parallel

airflow scheme is used, rather than a series configuration. In a parallel

configuration, each module is set up to receive the same amount of airflow and

thus the same cooling. To achieve this in the Prius, cabin air enters the pack

through a plenum that runs beneath the battery stack horizontally from passenger

side to driver side. The cross-sectional area of the plenum is largest at its

entrance and linearly decreases as it goes under the modules. Then the air flows

vertically through the gaps between each module (formed from dimples and

protrusions on side walls). Finally, the air enters into the top plenum. This

plenum’s cross-section increases linearly in the direction of the flow. With

this design, the pressure drop across each module is expected to be uniform and,

consequently, should lead to a uniform flow rate around each module. The air is

drawn by a 12 V blower installed above the driver’s side rear tire well. The air

is either exhausted to the boot or through a vent on the driver’s side C-pillar.

The fan has four settings, depending on the maximum temperature of four

monitored batteries. Toyota also monitors the inlet and outlet air temperatures.

The fan settings are off, low, medium, and high speed. The blower setting

depended on temperature and transitions with hysteresis depending on whether

temperature is increasing or decreasing.

The Battery Pack Computer

The Prius has a computer that’s solely dedicated to keeping the Prius

battery at the optimum temperature and optimum charge level. Both these

functions maintain the long life of the battery. Toyota have lab data showing

the Prius battery can do 290,000km of normal driving with absolutely no

degradation of the battery’s performance. This long life is largely due to the

computers control of the Battery pack.

from

The clean green

car company

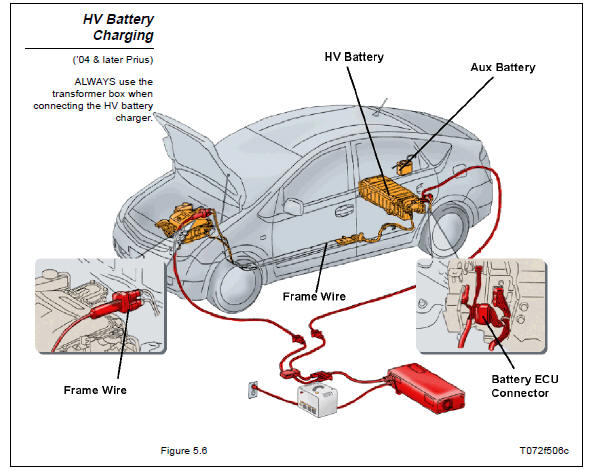

Battery System Diagnostics

In the event that a Prius has a HV battery that is too low for the car to be

started, Toyota dealers have a battery charging tool that allow them to charge

the HV battery from a standard AC outlet. Click on the image below for a pdf,

"High Voltage Battery Control Systems"

Battery charging system as used by dealerships to charge a

dead Prius battery

Power Inverter Top

The

power inverter is an electronic

device that takes the high voltage DC from the battery and turns it into AC that

can drive the motor. The inverter also converts the AC power from the

motor/generators back into DC to charge the battery. The unit contains special transistors called

IGBTs that perform the power switching

functions. Inverter teardown

article located

here.

Mechanical power-split device Top

The Prius has no manual or automatic

gearbox in the normal sense. Instead it has a type of

CVT

or more accurately called a "power split device".

The PSD divides

power seamlessly between the engine, motor and generator in any ratio. Its'

operation is similar in some regards to a differential. The actual PSD is about

the size of a mans clenched fist. For a description of how it works, with

animation, click HERE.

|